The triennial IFPE trade show and conference begins next week at the Las Vegas Convention Center. Slated for March 7-11, this event features nearly 500 fluid power exhibitors and gives attendees a chance to see the latest in hydraulic pump offerings. Here you can learn how they are constructed and used on mobile machinery. Below, you will find a listing of IFPE 2017 exhibitors who will be displaying their hydraulic pumps, as listed on the IFPE exhibitor list.

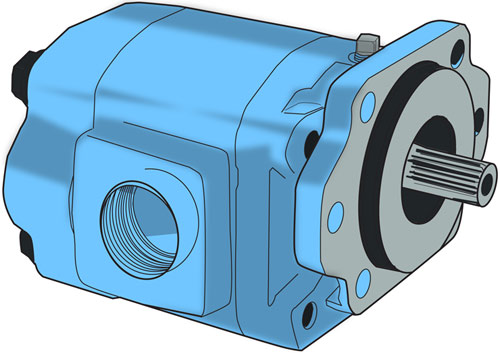

Hydraulic pumps are one of the most necessary components in a hydraulic system, as it is the pump that converts mechanical energy into hydraulic energy. A number of hydraulic pump designs exist, each with their pros and cons for system design and application.

Hydraulic pumps are one of the most necessary components in a hydraulic system, as it is the pump that converts mechanical energy into hydraulic energy. A number of hydraulic pump designs exist, each with their pros and cons for system design and application.

During selection, you must first know what pressure your system requires. For example, a vane pump is not reliable at pressures of 5,000 psi or higher, but piston pumps will suit that pressure range ideally.

Next, you must consider the pump’s displacement, which is the volume each design can pump during one rotation. This is normally expressed in measurements of cubic inches or centimeters per minute.

As stated earlier, certain applications work better with specific pump construction types. The main pump designs are piston, vane and gear, which can be further broken down into inside and outside types of gear pumps. Of these two, the outside gear pump is most commonly used because of its inexpensive, reliable and effective operation. This simple design is created with meshed spur gears, with one drive and one idle. Gear pumps are frequently used, particularly when price is a major driving factor.

Inside gear pumps use an inside gear arrangement, with more complicated construction and tighter tolerances. Because of these tight tolerances and complicated construction, they are much more costly, but are extremely efficient and quieter than the outside spur type. These designs are most often used in fixed-pump applications, such as servomotor driven closed-loop pump systems.

Used mostly in lower pressure industrial applications, vane pumps use a rotating group with rectangular vanes that push out via springs, creating centrifugal force or hydraulic pressure. The offset between the vanes and cam ring allows the pump to create flow, and in variable displacement vane pumps, the offset distance is what dictates volume. These designs are reliable, quiet and easy to repair.

If high pressure is a major design concern, then piston pumps are likely going to be the choice. The variable-displacement, axial-piston pump is the most common design in this category, while other piston designs being used on specific and rarer occasions. A highly efficient and very reliable design, the piston pump is also relatively easy to rebuild—even though it is not very inexpensive. They are available with countless control options, such as pressure-compensated, load sensing, remote pressure control, proportional control, etc. Also, the vast majority of closed loop pumps are axial piston type, because of the versatility and robust construction it offers.

Hydraulic pump manufacturers & suppliers at IFPE

(Please note, list may not be complete as changes are made regularly to the IFPE suppliers’ categories pages and companies are responsible for selecting categories.)

| Exhibitor Name | Booth Number |

| AAH Fluid Power Inc. | S83046 |

| Aber | SL80027 |

| ALA Industries Limited – Yuken Hydraulics | S82856 |

| Anfield Industries Inc | S80749 |

| Bailey International LLC | S83240 |

| Bezares USA | S82810 |

| Bosch Rexroth Corp | S80214 |

| Brevini Fluid Power | S82218 |

| Bucher Hydraulics | S81916 |

| Casappa Corporation | S81230 |

| Dana Incorporated | S84712 |

| Danfoss Power Solutions, Inc | S80730 |

| DDKS Industries | S80054 |

| Eaton Hydraulics Business | S80230 |

| Engineering Technology Services, LLC | S81342 |

| FluiDyne Fluid Power | S80634 |

| Fondmatic SpA | S80618 |

| Galtech | S82240 |

| GS Global Resources | S80654 |

| Han Dok Hydraulic Co | S83210 |

| HANSA-TMP s.r.l. | S80142 |

| Hartmann Controls Inc | S80640 |

| HAWE Hydraulik | S80529 |

| HEMA Endustri AS | S84730 |

| Hengli America Co. Inc. | S81440 |

| Hydraulex Global | S82652 |

| Hydrocontrol Inc | S82240 |

| Hydro Leduc | S83752 |

| Hydrosila | S82843 |

| IC Flow Controls | S83152 |

| International FPA | S83630 |

| Kawasaki Hydraulics | S80506 |

| KYB Americas Corporation | S80742 |

| Linde Hydraulics Corporation | S81129 |

| Miller Electric Mfg Co/Hobart Brothers | B7502 |

| Moseys Production Machinists, Inc. | S83652 |

| MTE Hydraulics | S81610 |

| Muncie Power Products | S82240 |

| Nachi America Inc | S81005 |

| Ningbo PHP Hydraulics Co., Ltd. | S81754 |

| North American Hydraulics | S82118 |

| Oilgear | S80514 |

| Parker Hannifin | S80242 |

| Permco Inc | S82130 |

| Poclain Hydraulics | S81640 |

| Power-Packer | S61250 |

| Professional Hydraulic Industrial Co., Ltd. | S82209 |

| Raymar Hydraulics | S80054 |

| Shanghai Guorui Hydraulic Technology Co. | S82352 |

| Shivam Hydraulics | S83739 |

| Sunfab North America | S83040 |

| Swanson Industries | G71207 |

| Transaxle | S82633 |

| U and T Tractor Spares PVT Ltd | G73612 |

| Veljan Hydrair Limited | S82618 |

| Walvoil Fluid Power Corp | S82240 |

| Webtec LLC | G70300 |

| Whitford Corporation | G74223 |

| White Drive Products | S81830 |

| Wooster Hydrostatics Inc | S80713 |

| WTC Machinery LLC | G71624 |

| Young Powertech Inc | S83318 |

Filed Under: Mobile Hydraulic Tips, Pumps & Motors, Slider