The loaded vs. unloaded hours of a compressor can show its operating efficiency.

A manufacturer of automotive products had a two compressor system that was designed for 100% redundancy—however, this system had never been fully implemented. Two air dryers, two large receivers, and two sets of filters were installed, but only two of the planned four compressors had been purchased.

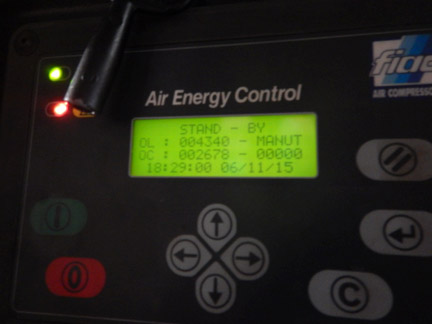

An auditor did a plant walk through and noticed that both compressors had many unloaded run hours; these units were each running almost 50% of the time, still consuming power, but producing no air, causing greatly reduced system efficiency. The auditor also noticed water in the compressed air and a significant pressure loss across the dryer and filters. The compressor controllers were electronic versions, but the load/unload pressure bands were both set at exactly the same value—causing the compressors to fight for control.

The auditor noticed that only one receiver and one dryer were being used at a time … when not in use, the second receiver and dryer were depressurized. Sizing calculations were performed, and it was found that, in the hot humid environment the equipment was operating under, the capacity of one air dryer was too small to process the air both compressors produced.

As a simple solution, the auditor recommended the second receiver and dryer be placed into service, both operating in parallel. This immediately doubled the storage capacity and greatly reduced compressor cycling, which reduced unloaded run time in half, in fact the second compressor often automatically turned off rather than running constantly. The pressure settings were adjusted to be slightly offset in cascade arrangement to better coordinate compressor control, making one compressor run base loaded and the other trim. None of these changes cost any money for equipment and has greatly improved system efficiency.

The plant manager reported a secondary benefit—previous to these changes, water was getting into a casting operation in the plant, causing pits, and spoiling some of their product. With these changes implemented, the dew point fell to normal and the system operated completely dry, even in very hot and steamy midday conditions. This eliminated the product quality problem and saved significant rework costs.

Learn more about compressor control in our next Compressed Air Challenge seminar in your area. Visit www.compressedairchallenge.org for more information.

By Ron Marshall for the Compressed Air Challenge

Filed Under: Pneumatic Tips, Slider