When a well-known automotive manufacturer needed its front and rear wheel arches molded by an injection molding specialist, it turned to Proper Polymers, a South Carolina-based company that manufactures plastic parts using the injection molding process.

The project presented considerable challenges, achieving a viable solution maintaining zero vestige, producing a cutting station that would handle two different size arches, and achieving an acceptable delivery date. The customer demanded this even though the gate faces inwards and is concealed in the assembled state. The timetable for the conception and realization of the project was very challenging. The original project partner was unwilling to produce a single cutting station that would handle both parts, therefore less than three weeks after the project started, Proper Polymers was left empty-handed and had to look elsewhere.

The company then contacted FIPA. According to its corporate claim “Challenge Accepted,” FIPA immediately began with design and construction of the degating station. Both the precise cut and the robot’s limited workspace presented challenges.

The company then contacted FIPA. According to its corporate claim “Challenge Accepted,” FIPA immediately began with design and construction of the degating station. Both the precise cut and the robot’s limited workspace presented challenges.

It is common for two parts to be molded in adjacent machines in the automotive industry, but in this case it was not an option. At the time there was only one injection molding machine available for this project, so the parts are molded alternately in the same machine.

If the workspace had been sufficiently large and adjacent machines were available, the two parts and two cutting stations could have been arranged next to each other and have the respective parts cut on separate cutting stations.

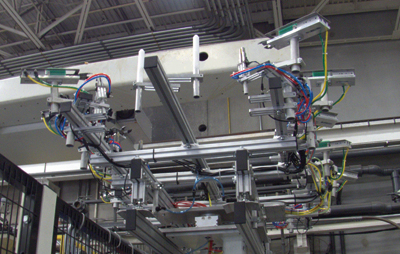

The solution soon became evident: a rotating mounted dual cutting station, which processes two wheel arches in parallel. When changing production from front to rear wheel arch the tool is changed and the cutting station indexed 180°.

A robot picks up two wheel arches from the injection molding machine and inserts them into the cutting station. FIPA air nippers remove the gates with zero millimeters of remaining gate. The robot then takes the two wheel arches and the runners out of the cutting station and places them on a conveyor.

Safety for process and personnel

Due to restricted space and safety concerns, the cutting station was mounted above head height and out of reach when in operation and while being rotated pneumatically. This ensures the blades of the air nippers cannot come into contact with workers in the work cell. FIPA parallel grippers hold the wheel arches in position during gate removal.

Several problems in the start-up phase were quickly identified and remedied. The gate geometry was difficult, the standard blade opening width, smaller than the gate, causing interference between the gate and the blade. To achieve sufficient clearance, stiffer springs were inserted in the blades and the cutting station’s drive was replaced with a custom solution designed to allow for the wider opening. This solved the issue with the blade opening dimension.

In addition, while they were not holding the part, the parallel grippers with HNBR pads designed to securely hold the wheel arch in position required greater opening tolerance to allow for easy insertion of the part into the fixture due to minor variations in presentation. This was resolved by modification to the mountings of the gripper’s HNBR pads on the non-visual side. This achieved a reliable operational tolerance while maintaining precise positioning of the part prior to degating.

Timely start of production

FIPA designed the cutting station in an expedited time—20 hours of design, 20 hours of assembly and testing. Although the system was very complex and delivery schedule tremendously challenging, FIPA nevertheless succeeded in delivering the system on time. The cutting station machines a pair of wheel arches in the allowed cycle time of the machine.

FIPA Inc.

www.fipa.com

Proper Group International

www.properpolymers.com

Filed Under: Pneumatic Tips