Here a machine saws wooden planks into slats. Pneumatic actuators from Festo press rollers into the wood to help the saw adjust to different wood types (while moving at 3 m/sec). Controls to adjust contact pressure include CPX terminal with a local CPX-FEC, Profibus interface, three CMAX modules, and an I/O module.

Pneumatic actuators come in an array of permutations for automation. Rod and rodless actuators are the two most common, though rodless are far more common in the U.S. Rodless actuators include bearings to address moment loads in X. Y, and Z. Tip: Avoid undersized pneumatic actuators for applications by accurately calculating application force; subtracting piston-rod area; accounting for the energy to overcome friction; and accounting for unusual application kinematics.

Note that most pneumatic-actuator applications are linear-stroke setups needing two or more position stops. Minimizing stop times in many pneumatic actuators are done by air cushions. Damping seals are another option. Choosing pneumatic actuators over electrical options is common in applications that need motion axes to work without electricity — where sparking poses a problem (as in applications that involve flammable materials for example).

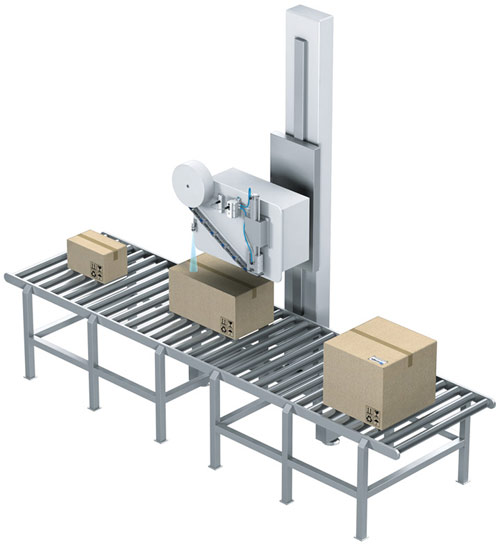

This label picker glues labels to packages of different sizes in one-second cycles as they pass on a conveyor. An analog distance sensor determines distance to the package to get label ejection 15 mm above each package. Here, a Festo DNCI cylinder works with a CPX controller and I/O module to deliver 50 to 500-mm strokes for advancement and return in less than a second.

Limitations include lack of total controllability and air consumption, but few actuators outperform pneumatic actuators in applications that need clean operation, low upfront cost, and high force-speed ratios. Even so, pneumatic actuators deliver moderate to high load at 120 in./sec or better. Plus advanced pneumatic actuators have wireless valve controls and sensors for IoT and predictive-maintenance functionality.

Another variation on pneumatic actuation: Bladders

Bladder actuators are another form of pneumatic actuation for short strokes and constant-force motion. Where appropriate they outperform other systems. In part positioning, footed bladder actuators output consistent lifting force for plates and other wide and flat loads and workpieces. Another application is automatic door seals to work as flood barriers and chamber closures. These inflatable actuators also work in material-handling applications. Such actuators can’t deliver on precision positioning, so only work where designs are forgiving on that parameter. They’re also unsuitable for point-source applications. That said, these actuators are capable of very accurate force control, and strokes can reach a couple inches.

Filed Under: Cylinders & Actuators, Pneumatic Tips