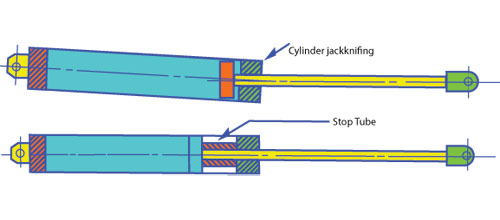

Cylinder stop tubes are simply metal collars or tubes that are placed around a hydraulic or pneumatic cylinder’s rod between the piston and head. They are designed for use only when a cylinder will have extra long strokes. Used primarily in horizontal applications, they help to prevent side loading and other column strength issues such as jackknifing or cylinder buckling. Side loading happens when the rod is retracted and pushed out of its normal travel route by a mass or force. This up, down or side bending force can cause rapid wear of a cylinder or even worse, a bent rod.

The stop tube provides side load support during those long extensions of the rod. Their use removes the risk of a piston bottoming out and prevents the cylinder from extending too far. This, in turn, avoids piston bending. Additionally, cylinder stop tubes decrease the risk of bearing surface overloads.

The stop tube provides side load support during those long extensions of the rod. Their use removes the risk of a piston bottoming out and prevents the cylinder from extending too far. This, in turn, avoids piston bending. Additionally, cylinder stop tubes decrease the risk of bearing surface overloads.

They should be used in place of installing oversized rods, which can cause misalignment and increased bearing loads.

Most often, cylinder stop tubes are recommended when cylinder stroke will be greater than 40 in., though some manufacturers recommend their use at 36 in. and above. Using them on shorter strokes unnecessarily lengthens the cylinder and increases weight. They also reduce a cylinder’s usable stroke length.

Sizing a stop tube is simple: installing 1 in. of stop tube is recommended for every 10 in. beyond 40 in. They are available in a variety of materials, including steel, brass and aluminum, among others.

Other things to keep in mind when designing a cylinder with a stop tube in mind include: the weight of the load and the type of movement it is (one or two directions, etc.); the cylinder’s cycle rate; the cylinder’s piston rod diameter; and finally, mounting style.

Filed Under: Cylinders & Actuators, Mobile Hydraulic Tips